Ikhwalithi yokusika i-bevel inquma ukuthi i-workpiece ingashiselwa ngokuqinile.Izinsimbi zendabuko zokusika ama-bevel zenziwa ngokuyinhloko ngokuphenduka, ukuhlela, ukugaya, ukugaya nezinye izindlela.Umsebenzi osikiwe ngokuvamile unamamaki okusika ajulile, ukuwohloka okukhulu kokushisa, igebe elikhulu kanye ne-arc angle engekho.Ukucutshungulwa kokuhlanganisa kamuva kunzima.Futhi inqubo yendabuko iyakhathaza, ukusebenza kahle kokukhiqiza okuphansi, ayikwazi ukuhlangabezana nezidingo zokusika kwe-bevel yevolumu ephezulu.Ukusetshenziswa kwemishini yokusika i-laser enezinhlangothi ezintathu-ntathu kulethe impumelelo enkulu ekucutshungulweni kwezingxenye zensimbi, ukuhlangabezana kangcono nezidingo zokusika zemikhumbi, i-aerospace, ukukhiqizwa kwezimoto, imishini yobunjiniyela nezinye izingxenye ezisekelayo ezinezinhlangothi ezintathu ezihlobene.Inqubo ye-grooving imi kanje.

1. Ipuleti eliwugqinsi lokusika kwe-bevel ephumelelayo

I-Grooving isekela ukusika amapuleti ensimbi kuze kufike ku-30mm ubukhulu;ipuleti le-laser cutting groove uma liqhathaniswa nenqubo yepuleti le-groove yendabuko, ukujiya kukhula kakhulu, kusiza izinkampani ukuthi zandise ububanzi bokucubungula kanye nezimo zohlelo lokusebenza, futhi zithuthukise kakhulu ukusebenza kahle kokukhiqiza.

2. Ukukhiqizwa okuzinzile nokucubungula kweqoqo

I-grooves yokusika yendabuko ithinteka kalula yizici zangaphandle, okubangela inqubo yokusika engazinzile kanye nekhwalithi engalingani yezingxenye ezicutshungulwayo, okuholela ekukhiqizeni okuncane;ukusebenzisa imishini ye-laser yokusika i-bevel kungaqinisekisa ngempumelelo ukunemba kokusika, ikhwalithi yokusika ezinzile nokunciphisa amaphutha okucubungula.Ilungele ukucutshungulwa kwe-batch yezingxenye ze-groove.

3. Sekela i-multi-slot cutting

Ikhanda lokusika le-laser elinezinhlangothi ezintathu ezihlukene lingakwazi ukulawula kahle i-axis yemishini ngokusho kobukhulu bezinto ezahlukene kanye nezidingo zokushisela, lidabule indlela evamile yokusika eqondile, esekela i-K, V, Y, U, X nezinye izinhlobo zokusika i-Slotting. , ukonga izinqubo zokukhiqiza, ukusika i-zero-gap ukunciphisa ubunzima bokushisela nokuthuthukisa ukusebenza kahle kokucubungula insimbi yeshidi.

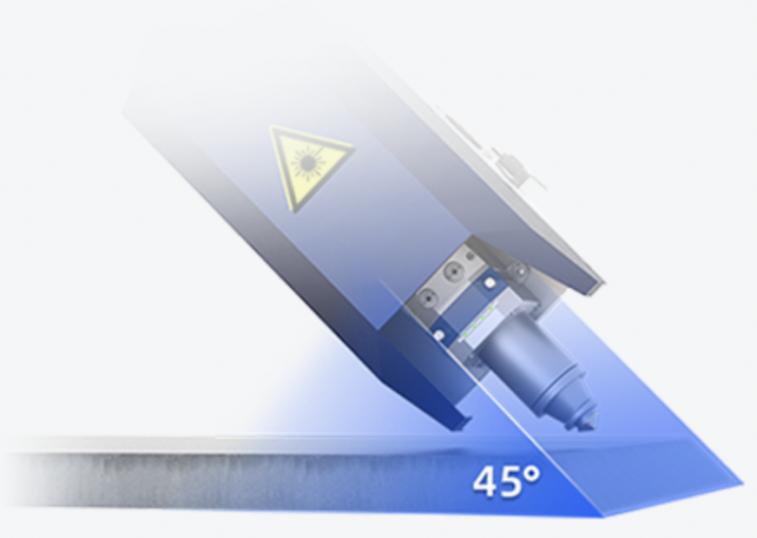

4. Thuthukisa ikhwalithi ye-grooving

Ikhanda lokusika le-laser le-3D le-axis emihlanu, lingasika futhi linciphise indawo emise okwe-3D yendawo yokusebenza;isekela ubuningi obungu-45° ukugoba ngesikhathi esisodwa, akukho ukucubungula kwesibili.I-workpiece ingasetshenziswa ngokuqondile ukushisela, ishintshe ngokuphumelelayo inqubo yendabuko yokushaya kanye nokunquma, ukunciphisa umjikelezo wokukhiqiza nokunciphisa izindleko zokukhiqiza.

5. Yehlisa izindleko zokucubungula i-groove

Ukucubungula izingxenye ze-groove zendabuko kudinga ukubamba iqhaza okukhulu kwesandla enqubweni yokusika nokupholisha;ukusebenzisa imishini ye-laser ukusika kungasiza amabhizinisi ukunciphisa ngempumelelo izindleko zabasebenzi kanye nokutshalwa kwezimali kwesikhathi, ukuxazulula ngempumelelo inkinga yokuqasha okunzima futhi onge izindleko zokukhiqiza.

Isikhathi sokuthumela: Dec-27-2022