Boleng ba ho seha bevel bo etsa qeto ea hore na workpiece e ka ts'oaroa ka thata.Li-bevel tsa setso tsa tšepe tsa tšepe li entsoe haholo ka ho reteleha, ho rera, ho sila, ho sila le mekhoa e meng.Sesebelisoa se sehiloeng ka kakaretso se na le matšoao a tebileng a ho itšeha, deformation e kholo ea mocheso, lekhalo le leholo le arc angle e sieo.Ts'ebetso ea morao-rao ea splicing e thata.'Me ts'ebetso ea setso ea khathatsa, tlhahiso e tlase e sebetsa hantle, ha e khone ho fihlela litlhoko tsa ho itšeha ka bongata bo phahameng.Tšebeliso ea lisebelisoa tsa ho itšeha ka laser ea mahlakore a mararo a mahlakore a mahlano e tlisitse katleho e kholo ea ho sebetsa likarolo tsa tšepe, ho finyella litlhoko tse ntle tsa likepe, sefofane, tlhahiso ea likoloi, mechine ea boenjiniere le likarolo tse ling tse tšehetsang likarolo tse tharo.Mokhoa oa grooving ke o latelang.

1. Letlapa le teteaneng le bevel hantle ho itšeha

Grooving e tšehetsa ho itšeha lipoleiti tsa tšepe ho fihlela ho 30mm e teteaneng;laser cutting groove plate ha e bapisoa le mokhoa oa setso oa groove plate, botenya bo eketseha haholo, bo thusa lik'hamphani ho atolosa mefuta ea ts'ebetso le maemo a ts'ebeliso, le ho ntlafatsa haholo katleho ea tlhahiso.

2. Tlhahiso e tsitsitseng le ts'ebetso ea batch

Li-grooves tse tloaelehileng tsa ho itšeha li angoa habonolo ke lintlha tse ka ntle, tse hlahisang mokhoa o sa tsitsang oa ho itšeha le boleng bo sa tsitsang ba likarolo tse entsoeng, tse lebisang tlhahiso e tlaase;ho sebelisa lisebelisoa tsa laser bakeng sa ho itšeha ka bevel ho ka etsa bonnete ba ho nepahala ho itšeha, boleng bo tsitsitseng ba ho itšeha le ho fokotsa liphoso tsa ts'ebetso.E loketse bakeng sa ts'ebetso ea batch ea likarolo tsa groove.

3. Tšehetsa ho itšeha ha li-slot tse ngata

Hlooho e nang le mahlakore a mararo a metso e mehlano ea laser e ka laola ka mokhoa o nepahetseng mochine oa lisebelisoa ho ea ka botenya ba lisebelisoa tse fapaneng le litlhoko tsa ho tjheseletsa, ho phunyeletsa mokhoa o tloaelehileng oa ho itšeha, ho tšehetsa K, V, Y, U, X le mefuta e meng ea ho seha Slotting. , mekhoa ea ho boloka tlhahiso, ho itšeha ka zero-gap ho fokotsa bothata ba ho tjheseletsa le ho ntlafatsa katleho ea ts'ebetso ea tšepe ea sheet sheet.

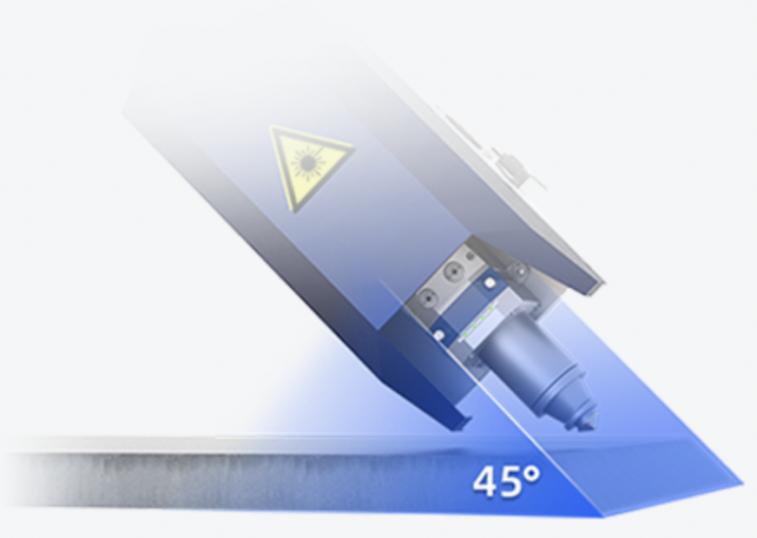

4. Ntlafatsa boleng ba grooving

Hlooho ea ho itšeha ea 3D ea li-axis tse hlano, e ka khaola le ho fokotsa bokaholimo ba sebopeho sa 3D sa workpiece;ts'ehetsa boholo ba 45 ° grooving ka nako e le 'ngoe, ha ho na ts'ebetso ea bobeli.The workpiece e ka sebelisoa ka ho toba bakeng sa ho tjheseletsa, ka katleho ho fetola mokhoa oa setso oa ho phunya le oa ho fokotsa, ho khutsufatsa potoloho ea tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso.

5. Fokotsa litšenyehelo tsa ho lokisa li-groove

Ts'ebetso ea likarolo tsa groove ea setso e hloka karolo e ngata ea matsoho molemong oa ho itšeha le ho bentša;ho sebelisa lisebelisoa tsa laser bakeng sa ho itšeha ho ka thusa likhoebo ka katleho ho fokotsa litšenyehelo tsa basebetsi le matsete a nako, ho rarolla bothata ba ho hira ka thata le ho boloka litšenyehelo tsa tlhahiso.

Nako ea poso: Dec-27-2022