Kudula kwa bevel kumatsimikizira ngati chogwiriracho chikhoza kuwotcherera mwamphamvu.Traditional zitsulo kudula bevels makamaka opangidwa ndi kutembenuka, planing, mphero, akupera ndi njira zina.Chogwiritsiridwa ntchito chodulidwa nthawi zambiri chimakhala ndi zipsera zakuya, mapindikidwe akulu amafuta, kusiyana kwakukulu ndi kusowa kwa arc angle.Pambuyo pake splicing processing ndizovuta.Ndipo njira yachikhalidwe ndi yotopetsa, yotsika kwambiri yopanga, siyingakwaniritse zofunikira za kudula kwa bevel.Kugwiritsa ntchito zida zitatu-dimensional zisanu-axis laser kudula kwabweretsa kupambana kwakukulu pakukonza magawo azitsulo, kukwaniritsa zofunikira zodulira zombo, zakuthambo, kupanga magalimoto, makina opangira uinjiniya ndi zina zothandizira mbali zitatu.Njira ya grooving ili motere.

1. Thick mbale bevel bwino kudula

Grooving imathandizira kudula mbale zachitsulo mpaka 30mm wandiweyani;laser kudula groove mbale poyerekeza ndi chikhalidwe groove mbale ndondomeko, makulidwe amakula kwambiri, kuthandiza makampani kufutukula osiyanasiyana processing ndi zochitika ntchito, ndi bwino kwambiri kupanga bwino.

2. Kupanga kokhazikika ndi kukonza batch

Mitengo yodula yachikhalidwe imakhudzidwa mosavuta ndi zinthu zakunja, zomwe zimapangitsa kuti pakhale njira yosakhazikika yodulira komanso mawonekedwe osagwirizana a magawo okonzedwa, zomwe zimapangitsa kuti pakhale zokolola zochepa;kugwiritsa ntchito zida za laser zodulira bevel kumatha kuonetsetsa kuti kudula kulondola, kukhazikika kokhazikika komanso kuchepetsa zolakwika pakukonza.Ndi oyenera mtanda processing wa mbali poyambira.

3. Thandizani kudula magawo ambiri

Atatu-dimensional asanu olamulira laser kudula mutu akhoza ndendende kulamulira zida olamulira malinga ndi makulidwe a zipangizo zosiyanasiyana ndi zofunikira kuwotcherera, kuthyola mwa ochiritsira liniya kudula njira, kuthandiza K, V, Y, U, X ndi mitundu ina ya kudula Slotting. , njira zopulumutsira zopangira, kudula kwa zero kuti muchepetse zovuta zowotcherera ndikuwongolera magwiridwe antchito achitsulo.

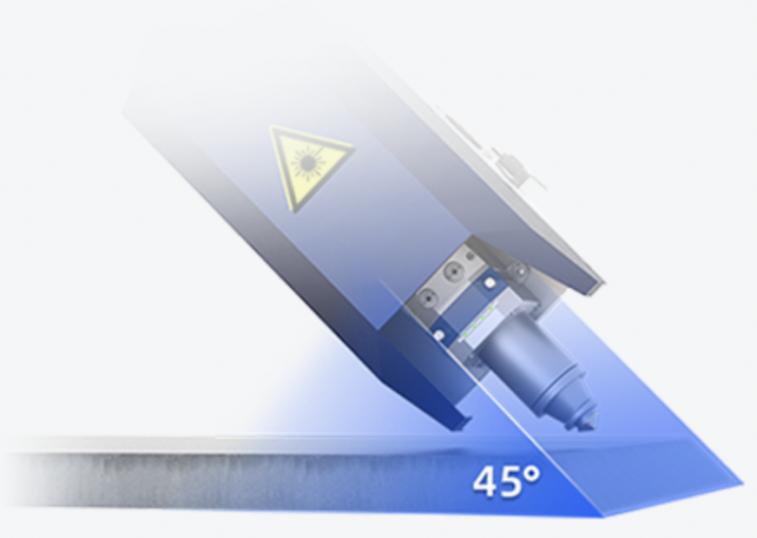

4. Kupititsa patsogolo ubwino wa grooving

3D asanu olamulira laser kudula mutu, akhoza kudula ndi chepetsa 3D zooneka pamwamba pa workpiece;kuthandizira pazipita 45 ° grooving nthawi imodzi kupanga, palibe processing yachiwiri.Chogwiritsira ntchito chitha kugwiritsidwa ntchito mwachindunji kuwotcherera, kusinthiratu njira yokhomerera ndi yochepetsera, kufupikitsa nthawi yopanga ndikuchepetsa ndalama zopangira.

5. Chepetsani mtengo wopangira groove

Traditional poyambira mbali processing amafuna zambiri pamanja ntchito kudula ndi kupukuta;kugwiritsa ntchito zida za laser kudula kungathandize mabizinesi kuchepetsa ndalama zogwirira ntchito komanso kusungitsa nthawi, kuthetsa vuto lazovuta zolembera ndikusunga ndalama zopangira.

Nthawi yotumiza: Dec-27-2022